Advanced Composites

Arvind has a vertically integrated play in Composites – from manufacturing of Glass Fabrics to providing end-to-end Composite solutions. We started our Composites journey in 2012, through a joint venture with Preiss Daimler Group (Germany). The Joint Venture – Arvind PD Composites – is engaged in manufacturing Glass Fabrics for Wind Energy, CIPP, Marine and other industrial applications. The products are certified by designated labs and are utilized by all the major Wind OEs. We produce 1000 T / Mth of Glass Fabrics in this facility.

Arvind forward integrated and started end product Composites in 2014 and now have a capacity of 1000 T / Mth – highest in India, and we offer a full range of solutions for multiple segments like building and construction, industrial, mass transport, wind energy, sports and, water infrastructure. We have expertise over a full suite of composite technologies – Pultrusion, hand layup, RTM, woven and knitted glass fabrics, grating and filament winding. We ensure the highest quality for all our composite solutions and meet global standards.

TECHNOLOGIES

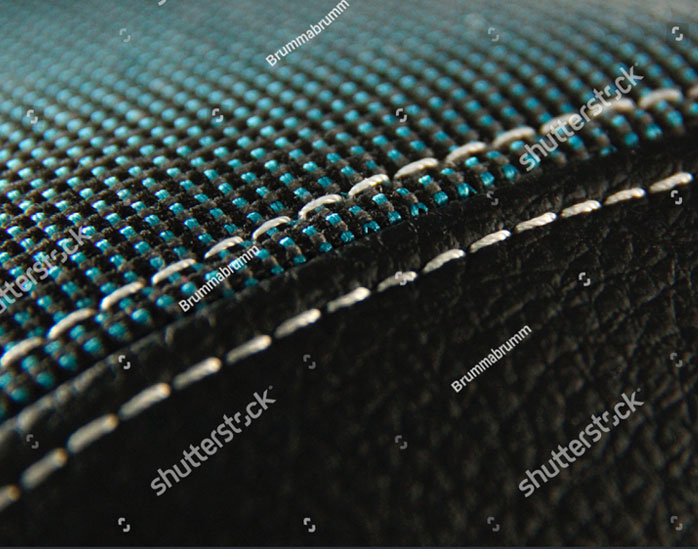

Stitch Fabric Technology and Glass Weaving

Pultrusion

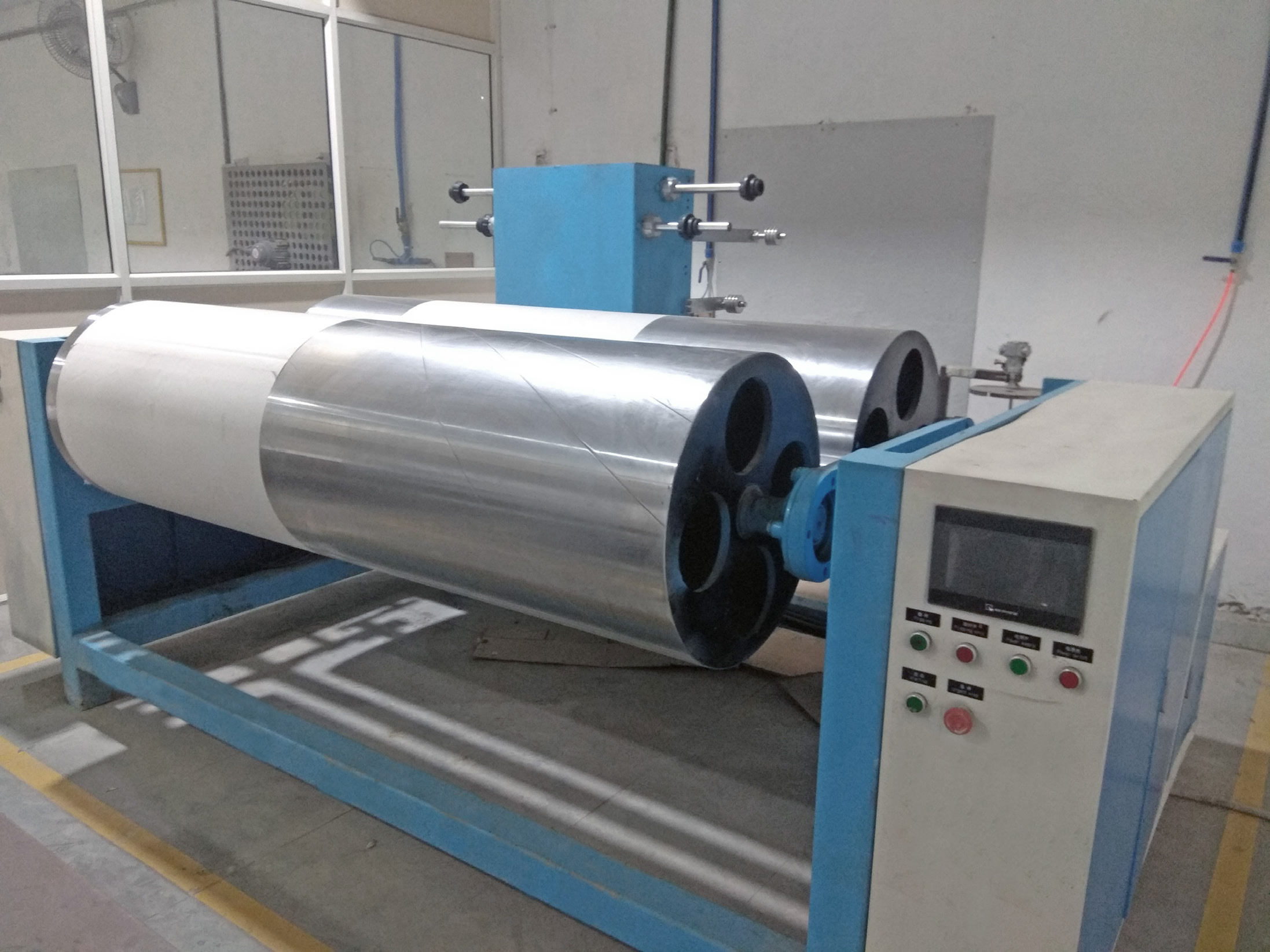

Filament Winding

Moulded Gratings

Contact Moulding

RTM / VARTM

Continuous Lamination

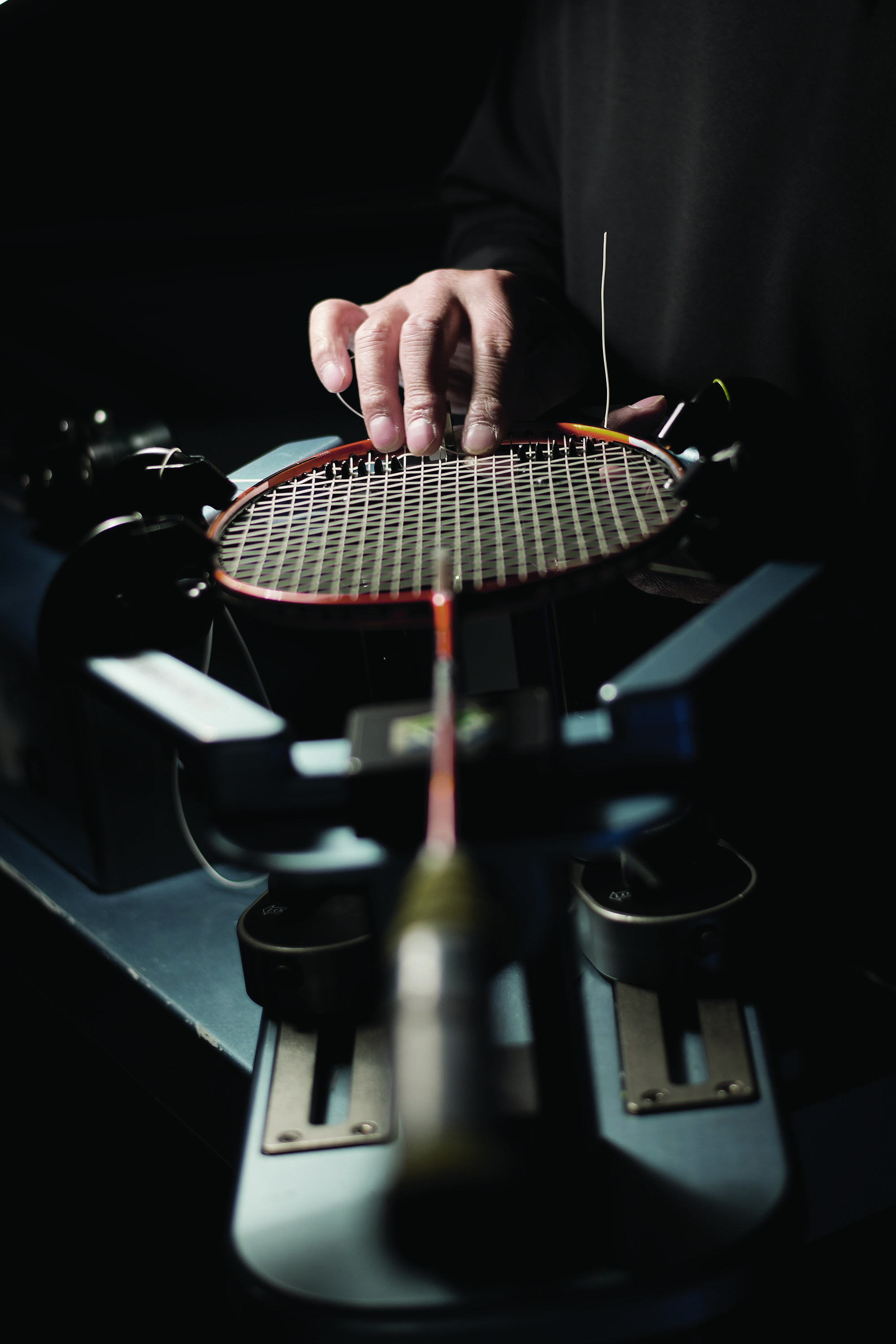

Prepreg moulding (sports)

OUR PRODUCTS

- Glass Fabrics-Wind Energy

- Industrial Products

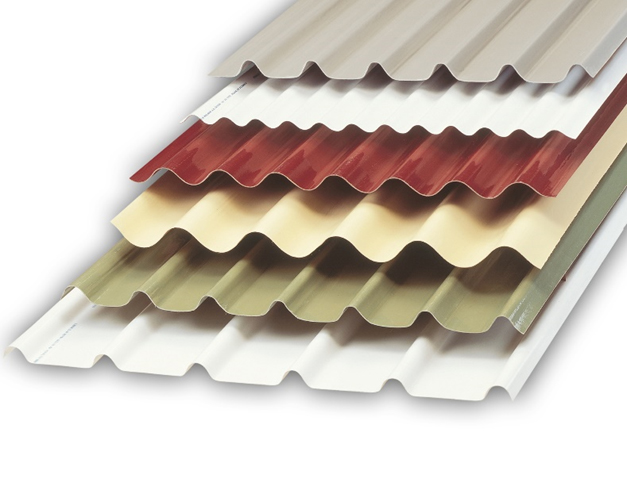

- Building and construction

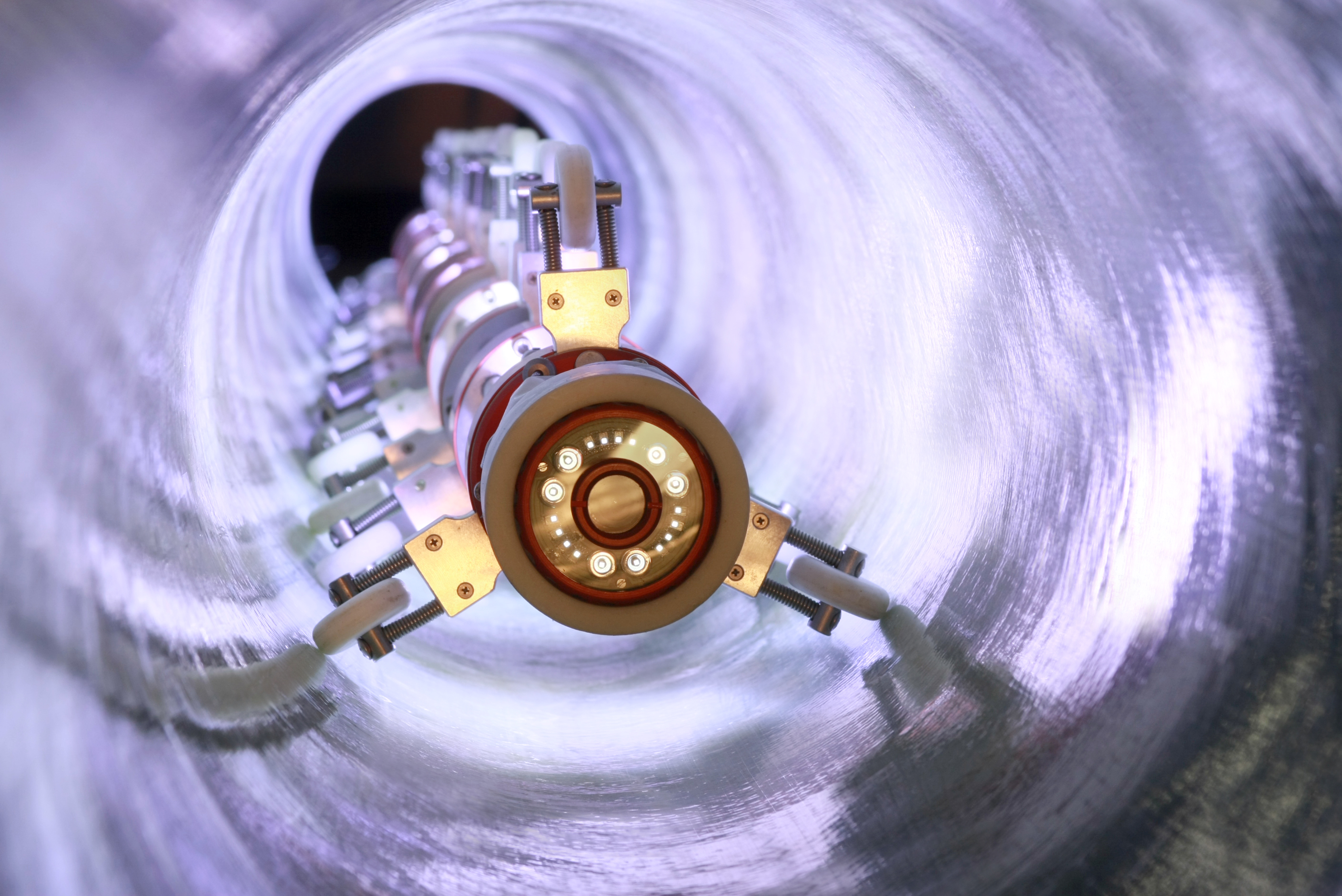

- CIPP (Cured In Place Pipe)

- Telecom

- Mass Transport Composites

- Sports

Glass Fabrics-Wind Energy

Industrial Products

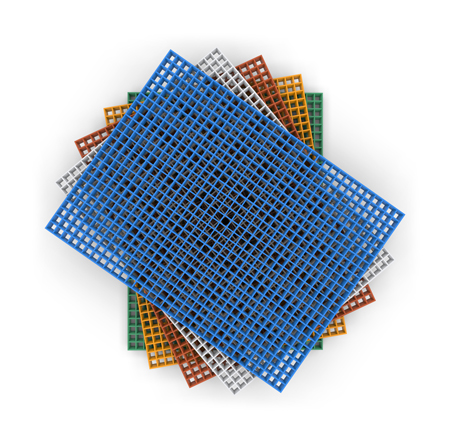

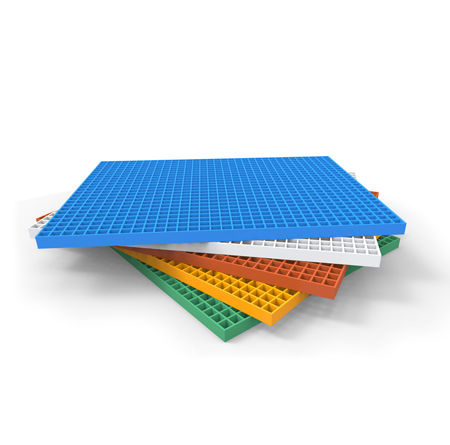

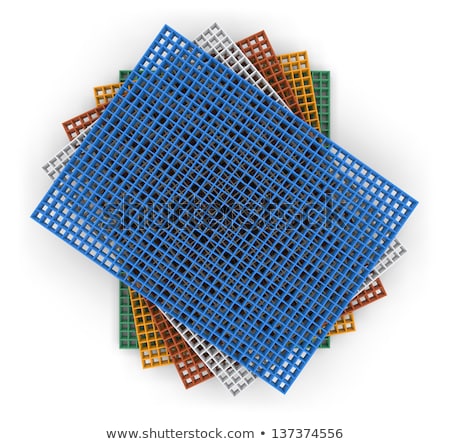

GRATINGS

Arvind offers a range of pultruded and molded gratings designed to meet the mass requirements for a variety of industrial purposes such as Walkways, Platforms, Protective Shielding, Machinery Housings, Raised Floors and Stairways that are lightweight & allows them to be an economical replacement for conventional gratings. Its anti-corrosive property allows utilization for a range of industrial and extreme environments.

Arvind’s FRP gratings are available in a wide variety of dimensions, with slip-resistant options such as anti-skid coatings, chequered plates. FRP Grating is often used when there are safety concerns due to liquid or oil on the floor. All gratings are in compliance with ACMA/ANSI standards which includes bottling lines, food processing plants, lift stations, commercial aquariums, lube oil facilities, plating shops, beverage canning facilities, chemical plants pulp, paper plants, Effluent treatment plants, and Water Treatment Plants.

CABLE TRAYS

Arvind’s cable trays are available with all accessories, are electrically insulated, UV protected and fire-retardant making them the material of choice for cable management systems.

CUSTOM STRUCTURES

LADDERS

Arvind’s FRP ladders are light-weight, safe and last longer than aluminum or steel ladders. Due to its electrical insulation properties, FRP ladders are ideal for any application where contact with Electricity can be a risk. Moreover, due to its non-corrosive properties, these ladders can last for decades even in highly corrosive environments. Conclusively, FRP ladders are light can be easily carried by a single person.

Arvind’s FRP ladders are available in various shapes and forms which can be useful for a variety of industrial and residential purposes. All the ladder profiles are in compliance with various global standards, including ANSI A14.5 and EN131.

Building and Contsruction

COOLING TOWER

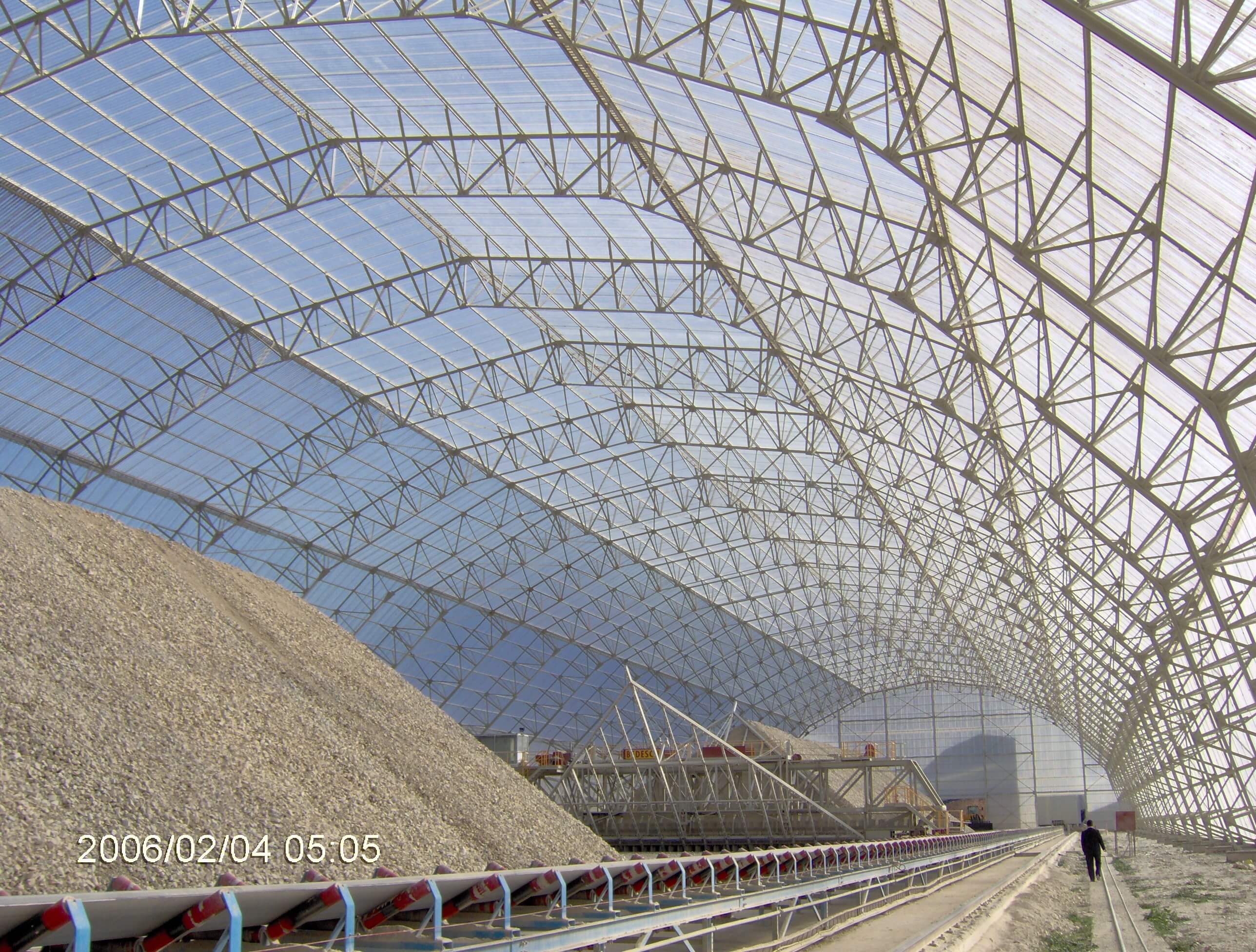

Pre Engineered Buildings

SPECIALITY APPLICATION

CIPP (Cured In Place Pipe)

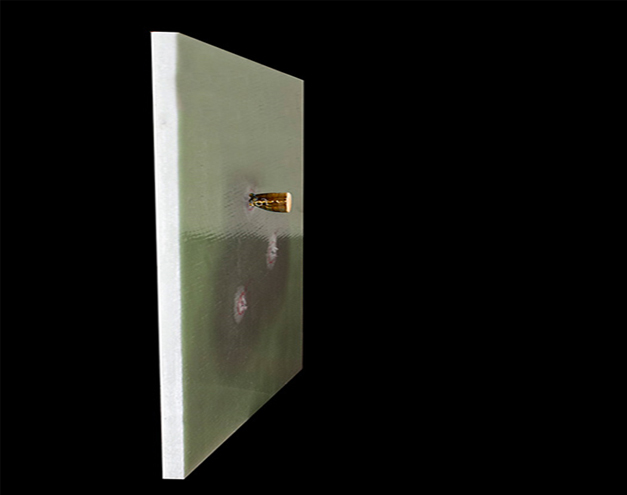

Telecom

RADOMES

POLES

TOWERS

Mass Transport Composites

We are working with large Mass Transport OEs to manufacture Composite solutions for various projects within India and abroad. We utilize various Composite Technologies such as Hand Lamination, RTM, VARTM, Prepregs, Adhesive Bonding and Painting. We have developed a range of products from Toilet Blocks, Composite interior and exterior panels and Complicated profiles.