Technologies-

Pultrusion:

Arvind Composites’ core technology is the Pultrusion process with a monthly capacity of 700 + MT/monthly. Through its technology partner Top Glass S.R.L (based out of Italy and the pioneers of Pultrusion technology), Arvind is capable of pultruding the most complex shapes possible- from fan blades and radomes to busbar supports and windmill spars .

Pultrusion is a continuous process for manufacture of composite materials with constant cross-section. The term is a portmanteau word, combining “pull” and “extrusion”. As opposed to extrusion, which pushes the material, pultrusion works by pulling the material.

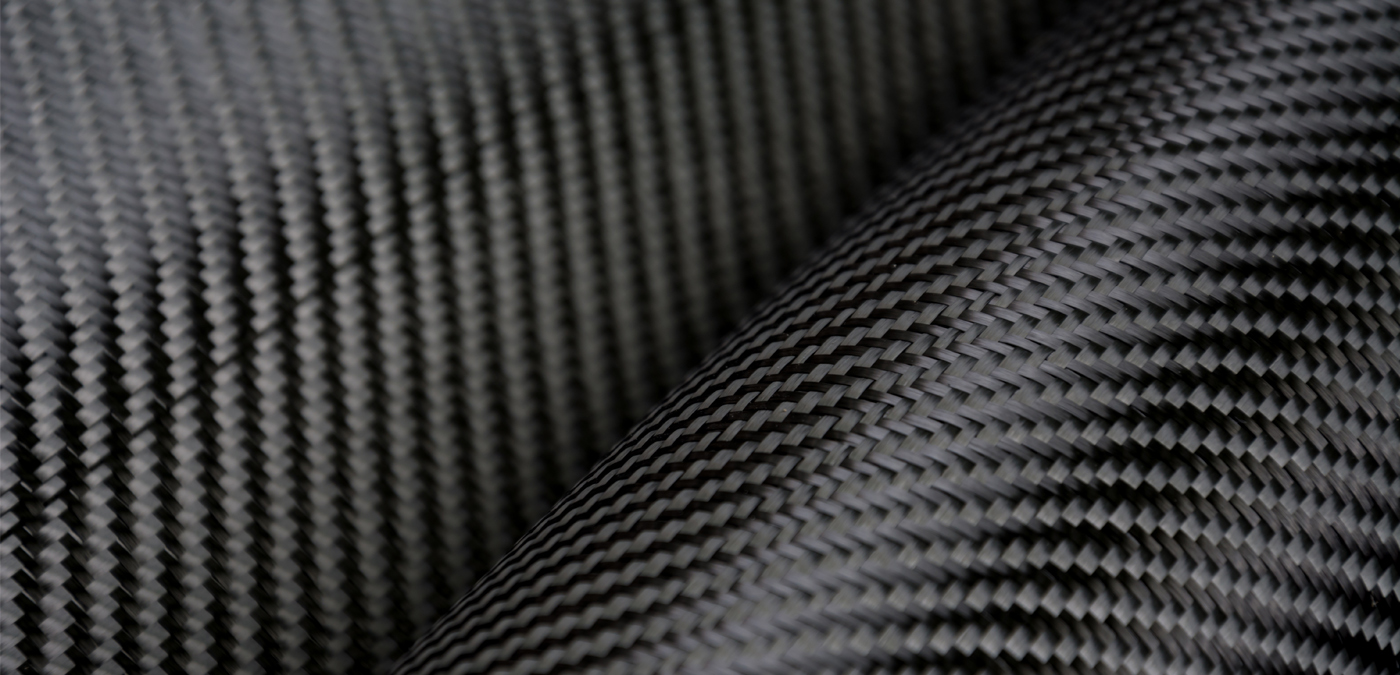

In the standard pultrusion process the reinforcement materials like fibres or fabrics or both are impregnated with resin, possibly followed by a separate preforming system, and pulled through a heated stationary die where the resin undergoes polymerization. The impregnation is either done by pulling the reinforcement through a bath or by injecting the resin into an injection chamber which typically is connected to the die. Many resin types may be used in pultrusion including polyester, polyurethane, vinylester and epoxy. Resin provides the resistance to the environment, (i.e., the corrosion resistance, the UV resistance, the impact resistance, etc.) and the glass / carbon fibres provides strength, in addition to safety from fire.

Filament Winding:

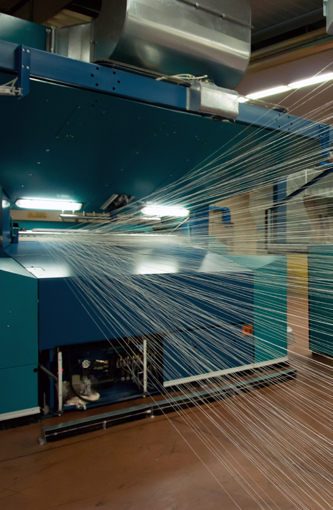

Filament winding is a technique mainly used for manufacturing pipes, tanks and pressure vessels. This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates around the spindle while a delivery eye on a carriage traverses horizontally in line with the axis of the rotating mandrel, laying down fibres in the desired pattern or angle. The most common filaments are glass or carbon and are impregnated in a bath with resin as they are wound onto the mandrel. Once the mandrel is completely covered to the desired thickness, the resin is cured. Once the resin has cured, the mandrel is removed or extracted, leaving the hollow final product. For some products such as gas bottles, the ‘mandrel’ is a permanent part of the finished product forming a liner to prevent gas leakage or as a barrier to protect the composite from the fluid to be stored.

Products made from this technique include reverse osmosis membrane housing, pressure tubes and pressure vessels, light poles, pipes and sporting equipments.

Moulded Gratings:

Manufactured in a heated mould, where continuous glass fibres are placed in alternating layer pattern and is thoroughly wetted with a thermosetting resin. This results in an integral, one- piece product that exhibits bi-directional strength and anti-corrosive properties. After the curing process, the part is ejected from the mould. And if required grit, for anti-slip characteristic is bonded on the top of the surface as a tributary procedure.

FRP gratings are lightweight and easier to fabricate, which leads to savings on labour and equipment during installation. This makes the total installed cost of Fibreglass gratings comparable to metal gratings. Combining these installation savings with longer life span and low maintenance costs, FRP gratings are used as the material of choice in range of applications. Moulded gratings are used in a range of industries like oil and gas, ETP & WTP plants, walkways and construction.

Contact Moulding:

Contact moulding is a process in which reinforcements are layed up by hand along with a resin mixture in an open or closed mould. The reinforcement fabrics are layed up layer by layer to get the desired thickness and properties. Once the material is layed up on the mould, the material is allowed to cure either using an oven or at room temperature. The reinforcement is usually glass fabrics (can be carbon / aramid) and are in the ratio of 30 – 40% of the overall composite; the resin can be polyester, vinylester, epoxy or phenolic and form the rest of the composite.

Unlike Pultrusion, contact moulding is used to make complex shapes using FRP. Contact moulding is used in a range of applications – all the way from architectural pieces for infrastructure to interiors of railway coaches and from fan stacks for cooling towers to chairs for large stadiums.

RTM / VARTM:

In resin transfer moulding (RTM), the closed mould is first pre-loaded with a reinforcing fibre matrix or preform. A liquid thermoset resin is introduced in the mould to impregnate the preform. Just like hand lamination, once filled the mould can be cooled at a controlled rate for optimal thermoset curing. Vacuum assisted transfer molding (VARTM) uses a partial vacuum on one side of a fiber mat to pull the resin in for complete saturation. The reinforcement is usually glass fabrics (can be carbon / aramid) and are in the ratio of 50 – 60% of the overall composite; the resin can be polyester, vinylester, epoxy or phenolic and form the rest of the composite.

It is used mainly to mould components with complex shapes and large surface areas, which require a smooth finish. Thus it commonly used in the transport industry for automotive and railway applications.

Continuous Lamination:

Continuous lamination can be considered as an advanced automated process for making Composites Panels or Sheets. The process starts with combining glass reinforcement with resins. The mixture is than made to pass through form rolls with help of a conveyor system. The form roll mechanism ensures that the thickness is uniform and the resin content remains consistent across the product. The mixture is than made to pass thorough a heating element which helps in curing the resin and form a composite sheet.

Arvind have tied up with Polser A.S (based out of Turkey) for the continuous lamination technology. Arvind Polser’s FRP sheets and panels offer ideal solutions for the construction industry, Cooling Tower Industry, Agriculture and Livestock Industry, Hygiene Industry, Food Industry, Automotive Industry, Highways / Advertising Industry.

Prepreg moulding (sports):